The Mill

At the beginning of the twentieth century, Jones and Laughlin Steel was the largest integrated steelmaking facility in the world built on a seven mile stretch of the Ohio River. This plant employed 14,000 at it’s peak, producing the steel beams, girders and military equipment that built this country and won it’s wars. It was the heart and soul of an American steel town, living through both the rise and fall of the steel industry.

Section II: North Mill

The North Mill, dark and gritty integrated departments, transforming the raw materials first into iron, and ultimately steel.

Chapter 3: Byproducts

Byproducts, began the dirty process of transforming dense bituminous coal into more porous hotter burning coke required for iron production.

Chapter 4: Steelworks

The Steelworks featured a Basic Oxygen Furnace(BOF), where the raw iron was transformed into processed steel ingots by melting in enormous ladles, or the Continuous Strandcaster into fiery red ribbons of steel

Chapter 5: Blast Furnace

The Blast Furnace embodies the true public perception of the raw iron making process. Here, iron ore pellets, coke and limestone are transformed into molten iron separated from slag impurities. The molten iron is then transferred in submarine ladles for further processing into steel.

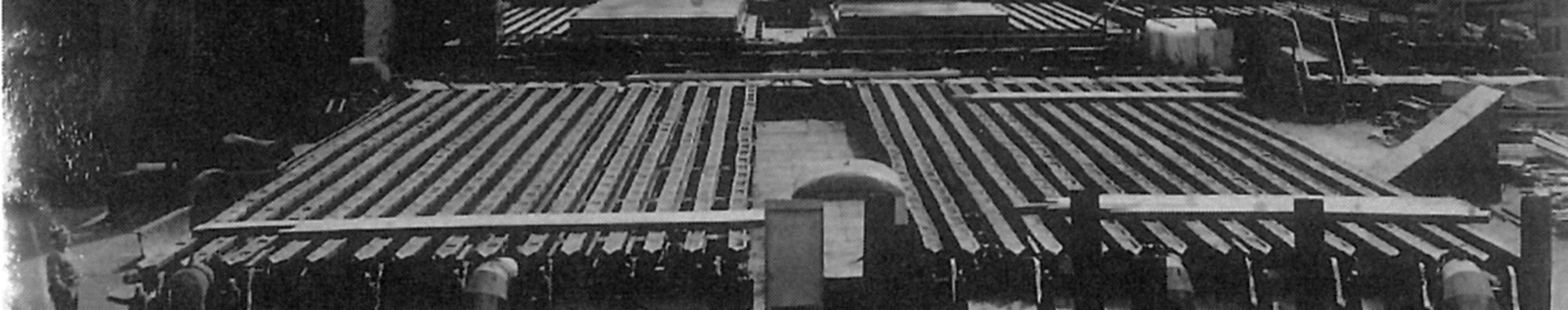

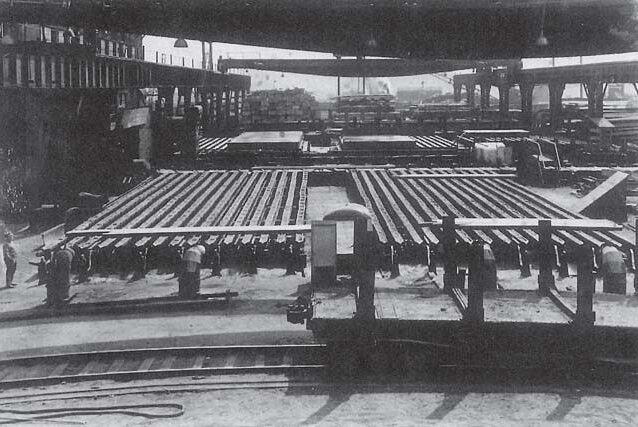

Blooming Mill

Here, the massive steel ingots are heated in the soaking pit, and turned into blooms or elongated rough slabs in the 44 and 45 inch Blooming Mill. The Bar and Billet Mill rolling process produces smaller, more manageable 18 and 21 inch steel bar and billets. Surface impurities are removed by the scarfing process, where they are manually burned off with a long torch.

Chapter 7: Strip Mill

The 44 Inch Hot Strip Rolling Mill takes superheated rough slabs through a shear and rolling process to fashion more manageable in size steel intermediary products.

Section III: South Mill

The South Mill held the conglomerate of finishing mills that produced the products ultimately sold for construction, building or development.

Chapter 8: 14 Inch Mill

The 14 Inch Structural Mill produced the Junior I Beam, channel beams, angle iron for construction, and rolled flat product for tire rims

Chapter 9: Welded Tube

The Welded Tube Department utilized an electric weld process to turn rolled flat steel into rigid pipe, followed by the continuous process produced pipe or the continuous process

without the folding step. This galvanized product is used for industrial gas piping, plumbing coupling and fittings and electrical conduit.

Chapter 10: Seamless Tube

The Seamless Tube Department took steel ingots that were reheated and transformed in the 30 Inch Round Mill. Here, the resulting shorter segments are fed through a rolling system producing 6 and 14 inch pipe. This standard product was typically used for oil and gas drilling applications.

Chapter 11: Tin Mill

The Tin Mill produced thin resilient strips of tin coated high carbon steel packaged in massive rolls. They were used to ultimately produce structural ductwork, corrugated product, appliance frame and food containers.

Chapter 12: Rod and Wire

This finishing mill produced high tensile strength braided steel wire and rope for guardrail, lifting and cable applications. It was said the Mill survived the economic downturn of the Great Depression making nails for construction and wire hangers.

Section IV: General Maintenance

The Maintenance Department unites the various construction and manufacturing trades, labeled “gangs” that kept the mill operational, 24 hours a day, 365 days per year.

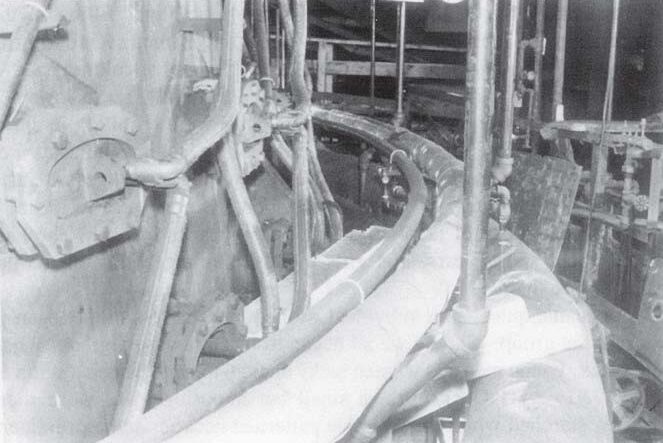

Chapter 13: Boiler Shop/Pipefitters

They maintained the high pressure piping systems moving steam heat and power, repairing boilers and water cooling systems integral to the steelmaking operation.

Chapter 14: Brick Layers

The bricklayers used heat resistant brick construction to protect and line industrial heat generating structures. The blast furnaces were massive structures, 200 feet tall requiring months to reline.

Chapter 15: Carpenter Shop

This group erected the critical scaffolding systems to allow other craftsman to repair the critical steelmaking infrastructure.

Chapter 16: Electricians

This group specialized in industrial electrical applications utilizing complex high voltage delivery systems. These systems required increased knowledge and experience to operate a power plant the size of a small city.

Chapter 17: Garage

The Garage provided interdepartmental heavy transport of materials on trucks throughout. They maintained their vehicles, provided fire and ambulance service functioning as a small city.

Chapter 18: Labor

The Labor Gang performed the miscellaneous clean-up task throughout, the dirty, strenuous and necessary tasks to keep a properly working mill functioning.

Chapter 19: Machine Shop

This shop made the steel or brass parts, fixtures, fittings and devices that kept the heavy machinery running.

Chapter 20: Mechanical

The Millwrights repaired the intricate manufacturing systems and machinery that made the raw and finished steel products.

Chapter 21: Riggers

The erection engineers were climbers working hundreds of feet in the air at times, cutting, burning, welding, assembling and disassembling the steelmaking apparatus.

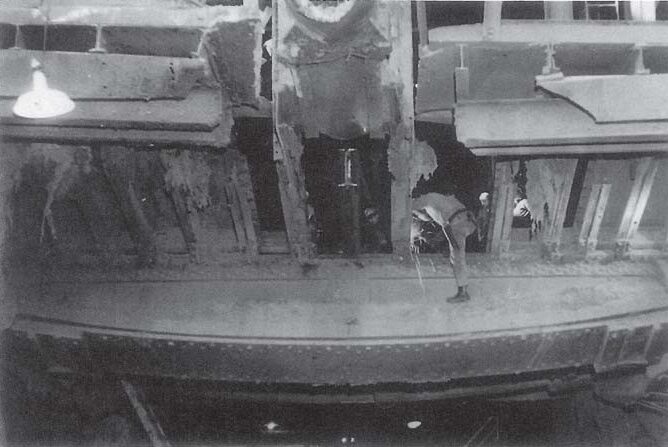

Chapter 22: Electric Crane

The Bull-gang erected, maintained and repaired the overhead gantry electric cranes, the lifeblood of the steelmaking process capable of moving 5-500 tons, whether moving the steel ladle or finished product.

Section V: Service

The Service Sector provided support to the other employees and departments throughout the Mill.

Chapter 23: Clerical

This service performed typing, keypunch, filing and tabulating functions for the administrative and accounting departments.

Chapter 24: Union

The United Steelworkers Union, USW 1211 in Aliquippa allowed union, organization, representation and collective bargaining for it’s rank and file workers after the 1937 National Labor Relations Board(NLRB) and Wagner Act were upheld as constitutional in the landmark US Supreme Court decision.

Chapter 25: Management

The backbone of the management organizational process was the working mill foreman and sub-foreman system working closely with the rank and file employees.

Chapter 26: Security

This plant the size of a small town had it’s own police force. It maintained entrance and exit security, patrolling the premises and assisting in investigations.

Chapter 27: Health Center

The health center provided routine care, occupational medicine services, lab and X-ray services and emergency care for hundreds of employees a day. The company and employees eventually built their own hospital to provide care to the workers and their families.

Chapter 28: Railroad

The rail system involved Aliquippa and Southern(A&S) line moving raw and finished product inside the plant. While the Pennsylvania and Lake Erie(P&LE) railroad moved product outside the gates to the nation’s rail system and the remainder of the country.

Chapter 29: History of Aliquippa

From the town of Woodlawn at the turn of the century to the incorporated city of Aliquippa, Pennsylvania

Chapter 30: Epilogue

After the fall, support businesses relocated, people moved away, but the Aliquippa and it’s people and proud traditions survived.

Blast Furnace water tender

Blast Furnace water tender Overhead Crane

Overhead Crane Site of overhead crane collapse in Bar and Billet Mill

Site of overhead crane collapse in Bar and Billet Mill United Steelworkers of America, Steelworkers Organization of Active Retirees

United Steelworkers of America, Steelworkers Organization of Active Retirees Author- Rade B. Vukmir

Author- Rade B. Vukmir Rade Beukovic

Rade Beukovic